Ultrasonic cleaner waves are sound waves sent above 20,000 Hz (20 kHz or 20,000 cycles per second), or greater than the frequency detectable by people. Acoustic waves are produced by the resonance of an item, which triggers the air molecules around it to vibrate. These resonances create our tympanums to vibrate, which the brain, after that takes sound. When the initial vibration is high-speed, so are the sound waves, and the pitch of the sound produced is too high for the human ear to hear.

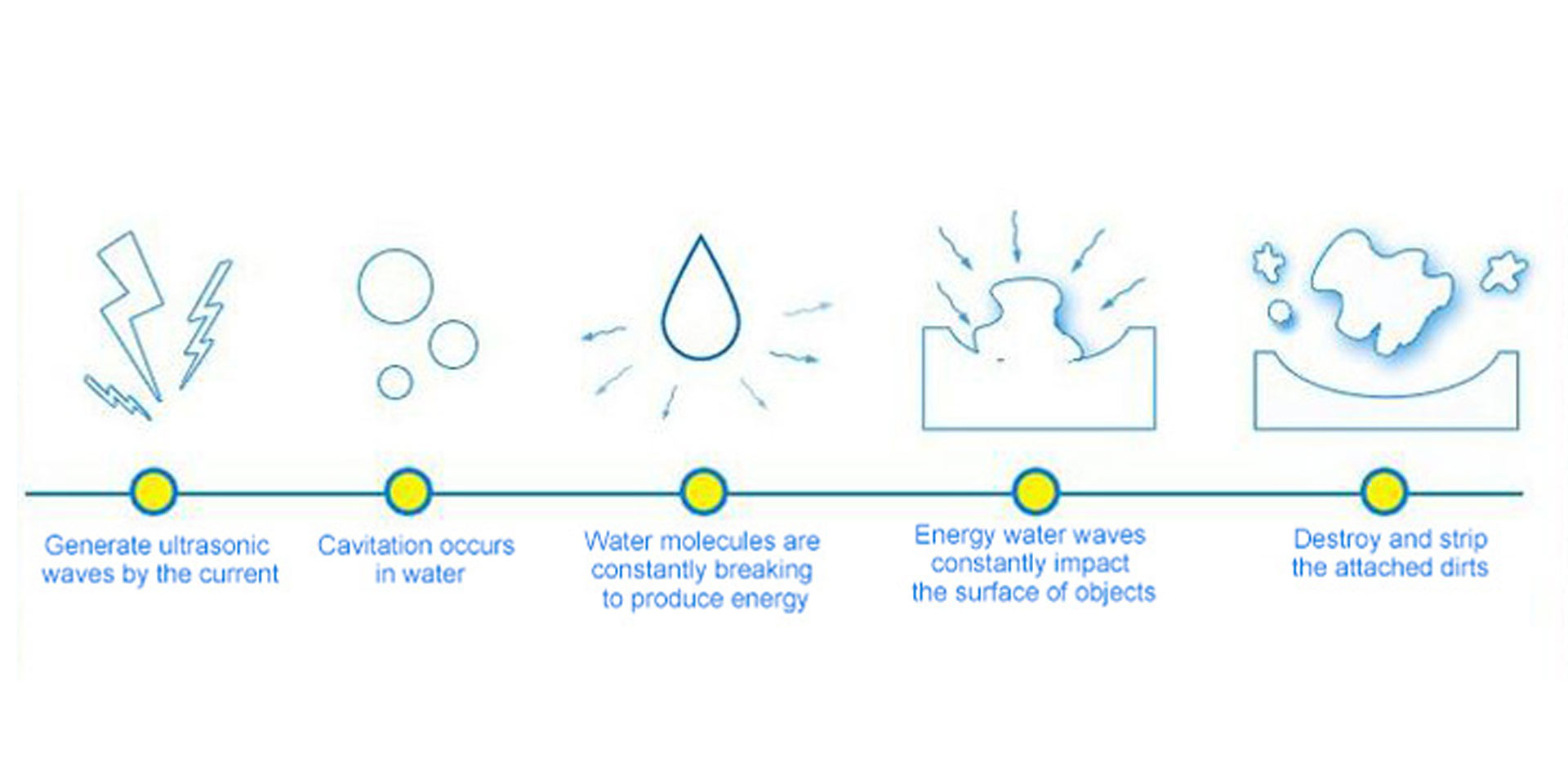

In the natural world, pets like dolphins and bats utilize these ultrasonic waves to connect, but humans have discovered functional applications. The most commonly known is clinical ultrasonography, although in the last 30 years, some organizations have found highly effective, chemical-free cleaning applications and innovation. Ultrasonic cleaning machines operate in a similar method to a loudspeaker. Other than the ultrasonic cleaner waves take a trip at a much higher regularity and through the water as opposed to air. A high-frequency digital generator that produces ultrasonic waves is connected to a diaphragm, a conical or flat structure comparable to the noticeable cone-shaped section. The generator shakes the diaphragm at an incredibly high frequency, usually between 25 and 170 kHz, inside a specifically designed water storage tank. The ultrasonic cleaner waves produced the water molecules to shake rapidly, producing pressure waves of compression and expansion within the water. During the growth stage, or rarefaction cycle, the liquid is torn apart, producing cavitation bubbles. These bubbles are where ultrasonic cleaning technology is born.

How does Ultrasonic Cleaner work?

Ultrasonic cleaning is a beneficial type of cleaning where dirt bits are completely and swiftly got rid of from a range of things. Items are immersed in a container with fluid, which is after that hit with high-frequency acoustic waves. The acoustic waves develop a gentle yet effective rubbing brush activity in the fluid that clean up all surfaces of the items consisting of deep pores and holes.

Ultrasonic energy creates the rapid development and collapse of little bubbles in the fluid, referred to as cavitation. A big burst of power creates bubbles that swiftly raise in size until they burst versus the surface area of the item.

Power conversion with transducer

The conversion to ultrasonic energy is assisted by a transducer, a vital part of ultrasonic cleaners. The transducer converts electrical energy into the high- frequency acoustic wave called ultrasonic energy.

A transducer’s efficiency determines both the time required to clean and just how thoroughly a surface area is cleaned. A transducer mediocre consumes more power and increases the length of cleaning time.

Other variables that affect ultrasonic cleaning efficiency consist of power, warmth, capacity, cleaning solution, and the length of the cleaning cycle.

Kinds of transducers

There are two kinds of transducers: piezoelectric and also magnetostrictive.

Magnetostrictive transducers operate on the concept that iron-rich metals increase and agree when positioned in a magnetic field. This expansion and contraction cause the canister in the device to resonate and create ultrasonic waves.

Piezoelectric transducers use crystals with electric buildings. The crystals alter form when electricity is passed through them and resume their original shape when the system is turned off. The resulting resonance makes waves that create ultrasonic energy.

Ultrasonic cleaning applications

Ultrasonic cleaners can likewise be personalized to suit the specific needs of a manufacturing facility, health centre or various other companies. With thousands of commercial and industrial cleaning applications, ultrasonic cleaning is widely used across lots of markets. Ultrasonic cleaners are tailored to the sorts of components that they are cleaning up. Table leading and benchtop cleaners, for example, are best for cleaning tiny or delicate parts like bearings, surgical instruments, optical parts, machined parts, tiny equipment as well as carburettor components. Precision cleaning is utilized for cleaning and recovering delicate items that may have been damaged by traditional cleaning approaches.

Benefits of ultrasonic cleaning

Ultrasonic cleaning conserves time and money:

- up to twenty parts can be cleaned at one time

- modern technology is easy to use and only calls for one driver

- life of components is extended because of mild cleaning

- highly effective cleaning suggests all pollutants are gotten rid of in preliminary

Sorts Of Ultrasonic Cleaners

Ultrasonic cleaning systems have been available in a range of dimensions, based on the equipment’s planned use. Their storage tanks are commonly constructed from stainless steel and also are rectangular in design. Transducers are placed, put or bonded to the container, most often to the bottom, yet devices can be customized with side-mounted, hanging or bulkhead-mounted transducers.

Table Top Ultrasonic Cleaners

These devices are tiny enough to rest on a workbench, table or shelf and are relocated conveniently, such as EraClean Ultrasonic Cleaner, which can clean larger items like eyeglasses, and easily carry with you on-the-go. They are straightforward in design, with solitary storage tanks ranging in size from half-gallon to 8 gallons and higher regularity levels (though 40 kHz is the most common), making it risk-free for also very delicate items. They are intended primarily for lighter obligation applications, including optical components, small equipment, machined parts, bearings, surgical instruments, and carburettor parts.

Best & First* EraClean Ultrasonic Cleaner for Jewelry Eyeglasses Watches Coins Razors Dentures 12 Ounces(340ML) 45000Hz

Bench Top Ultrasonic Cleaners

These systems have the tiny dimension and mobility of tabletop equipment but offer more enormous ability alternatives and more cleansing power. The standard frequency utilized is 40 kHz, yet this unit style can be custom-made at lower and higher frequencies. Benchtop systems can have containers as large as 20 gallons, which makes them better for high quantity. They can be used even in extreme atmospheres, such as out at a natural calamity or wildfire website. Bench leading tanks are designed for challenging or unusual cleaning work and are usually utilized in the machining, automotive, marine, and 3D printing markets.

Large-capacity Industrial Ultrasonic Cleaners

The biggest ultrasonic tanks can include storage tanks as huge as 1,000 gallons or more. These devices are indicated for applications calling for reduced regularities (25-40 kHz), including larger or heavy equipment such as over-sized production parts, automobile and marine parts, and big music tools. Systems might have multiple integrated phases, consisting of rinse and completely dry terminals, and are sometimes automated.